English

English

2025.04.28

As a pioneer in flip chip display panels, Lpdisplay has been deeply engaged in the field of flip chip COB LED displays, achieving remarkable results. So, why focus on flip chip COB LED displays? Let's explore the inherent technical advantages of this technology.

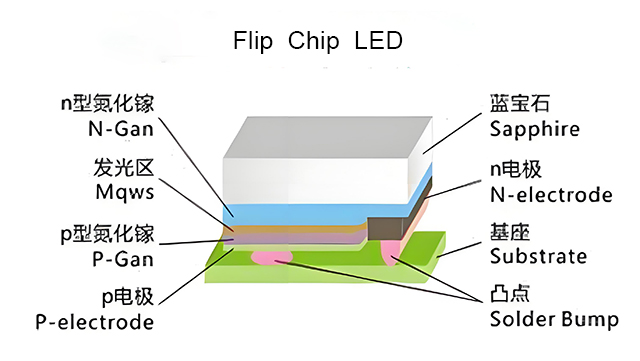

Flip chip COB technology employs solder paste to create electrical and mechanical connections between the chip and the substrate, eliminating the need for brackets found in traditional SMD packaging. This allows for smaller pixel pitch and higher screen resolution. Additionally, this design minimizes the granularity of images, resulting in a softer and more delicate display quality.

In the flip chip COB structure, the LED chip is directly encapsulated on the PCB and entirely coated with materials such as epoxy resin. This design offers superior protection compared to conventional SMD packaging, providing multiple advantages including waterproofing, dust resistance, moisture resistance, electrostatic protection, and impact resistance.

Flip chip COB technology facilitates a more direct contact between the LED chip and the PCB, significantly shortening the thermal conduction path. This enhancement boosts heat dissipation efficiency and reduces thermal resistance, thereby increasing the stability and reliability of the display, especially under prolonged high-load conditions. The bond strength between the chip and the substrate is exceptionally high, with the strength of the solder exceeding 100 times that of conventional gold wire bonding, ensuring durability.

By eliminating the connection wires between LED light-emitting chips, flip chip COB technology results in a thinner and lighter packaging layer, which reduces thermal resistance. This improvement contributes to higher light output efficiency and enhanced color uniformity, making it particularly crucial for applications that demand high-quality visual displays.

Although the technical threshold for flip chip COB technology is relatively high, its production process is straightforward. It eliminates the need for reflow soldering and brackets, allowing for direct soldering or the use of special adhesives to secure the chips. This simplification reduces production complexity and enables repairs in the event of a malfunction, thereby lowering production costs and enhancing overall efficiency.

With the trend of shrinking pixel pitch and miniaturizing chips, the advantages of flip chip technology have garnered significant attention in the industry. Moving forward, Lpdisplay will continue to innovate and develop in the field of flip chip led displays, gaining deeper insights into consumer needs. We aim to provide competitive, safe, and reliable HD LED display, visual display technologies and big data products, consistently delivering higher quality, more efficient, and smarter small pixel pitch LED display solutions.